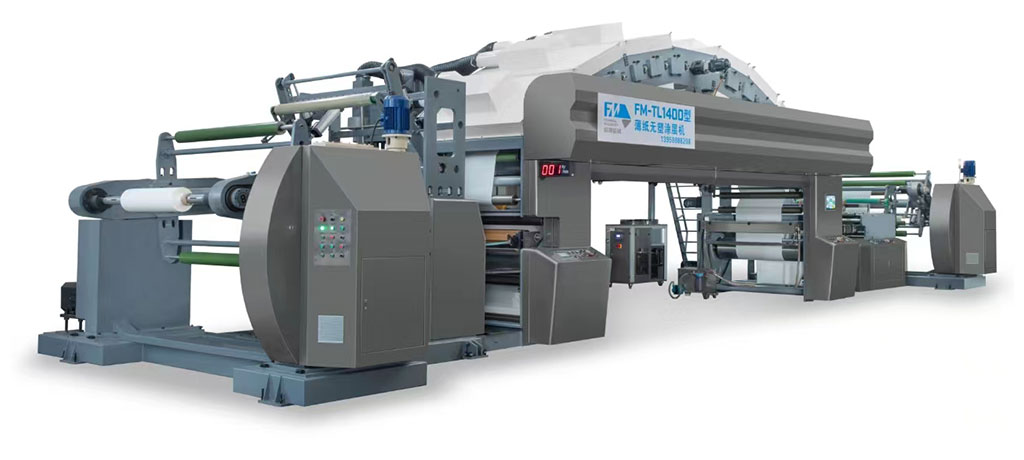

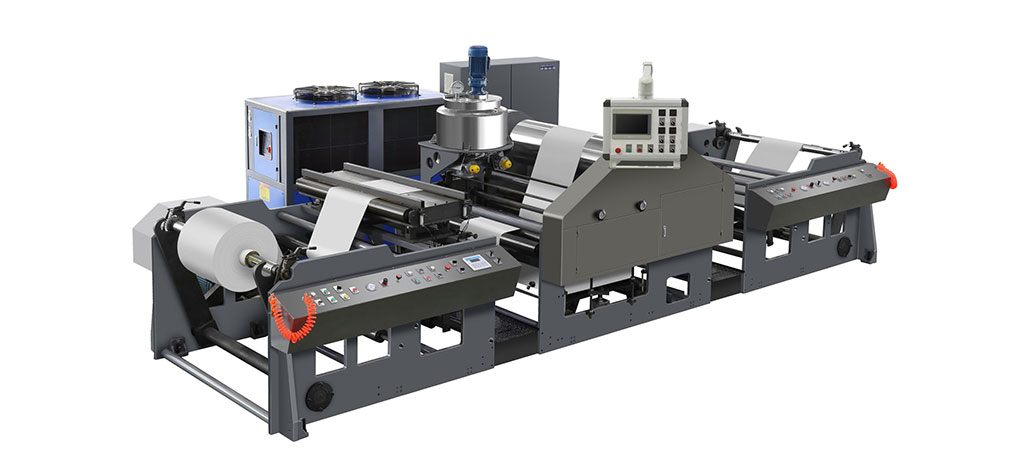

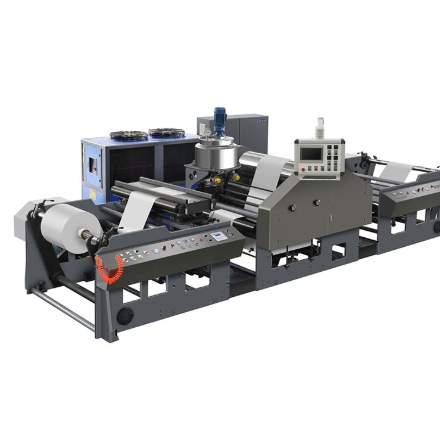

| Specification | ||

| Coating width | 1400mm | |

| Coating method | Gravure reverse coating / gravure front coating | |

| Coating speed | 80-240m/min | |

| Feeding form | Turret type automatic paper splicing | Max.unwinding diameter 1200mm |

| Winding method | Turret automatic roll change | Max.rewinding diameter 1200mm |

| Drying method | Electric heating, natural gas, steam, etc. | |

| Applicable material | Straw paper, three-side seal paper bag, middle seal paper bag, hamburger paper | 28-120g |

Note: as the products are developing day by day, the technical data are subject to change without notice